As you know the MOLOTOW™ PREMIUM 400ml has a strong covering-power and UV-resistance – due to its 4 times ground pigments normally to be found only in car paint. Conventional SPRAYPAINTS only use single ground pigments and thickener to produce an alleged covering-power which isn’t able to resist UV-radiation and atmospheric conditions for too long – the result is: that it is necessary to apply several layers of lacquer in order to reach maximum opacity and the color is fading away in short time. Only few examples of vehicles, especially cars, that have been painted with SPRAYPAINT can be found on the internet. One reason is the general assumption that with a tool like SPRAYPAINT it is not possible to reach the precision needed for such a kind of work and another reason is the difficulty resulting from the handling of SPRAYPAINT. In common opinion a paint job on a car is done with a spraygun or airbrush where thin layers of paint and a smooth surface can be achieved. Spray paint is seen as a thick or even “grumpy” material which smears and creates paint drops all over. When browsing the internet for spraypainted cars one can find many blotted vehicles with thick layers which perpetuate the stereotypes that twine around Graffiti. Here is another proof why MOLOTOW™ PREMIUM SPRAYPAINT and MOLOTOW™ ONE4ALL Markers are perfect Products to be used on Cars or Motorbikes. Have a look yourself, two great Videos and a few Photos can be seen after the jump!

“I wanted to show that it can be done very clean, as long as the skills allow it. Painting a car is a huge challenge and entails risks. Because of the individual style I was not allowed to make a mistake. One drop of paint and the body part could’ve been grinded and redone. It was also only possible to a limited extent to correct mistakes because every layer of paint is another raise which reflects in the quality and evenness of the surface.” (Bastique)

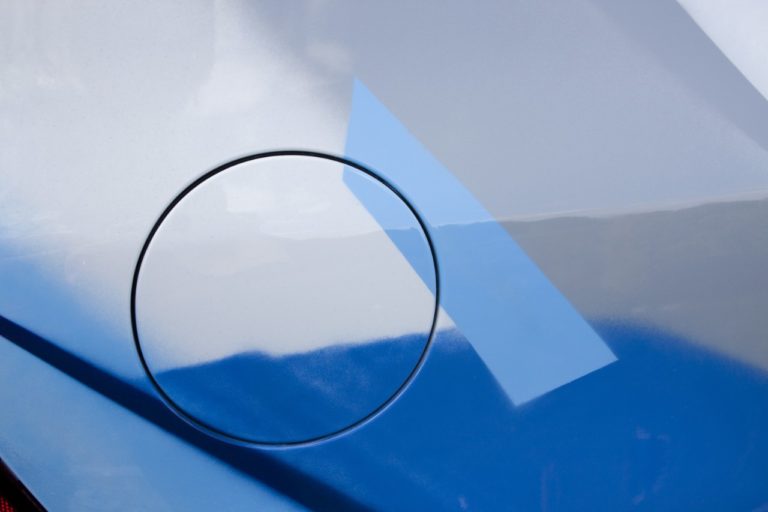

The vehicles were sanded, spraypainted with MOLOTOW™ PREMIUM respectively designed with MOLOTOW™ ONE4ALL Markers, clear coated, intermediate sanded and clear coated again, just like it’s done on a regular paint job. This led to an excellent surface quality which surprised the vast majority of the audience. The exceptionalism of this method and the high quality result was responsible for the almost unanimous enthusiasm simply because it hasn’t been done in that grade before.